A lot of you may have heard about 3D printing on the news as this new technology that will revolutionize the world.

While 3D printing actually isn’t a new technology. 3D printing was invented back in the 1980s by an industrial designer in America called Chuck Hall during the 80s, 90s, and early 2000s. We saw treaty printing hit the market in large factory floor machines, large industrial machines with limited choice, and huge expensive costs. Only in the past five to 10 years have we seen 3D printing hit a new era, a new form that we call desktop 3D printing. But in desktop, 3D printing.

There are many different forms in it. From what we call the riprap kit is a kit that you assemble yourself to more polished and plug and play.

what is 3D printing?

3D printing formerly known as additive manufacturing is the process of creating an object through a layer by layer. What I mean by this is if you could imagine an orange. Now, imagine cutting that orange up into slices. Now, put those slices back together as they were cut.

I’ll give you another example. Imagine a chocolate syringe and a piece of paper. Draw a circle on the piece of paper of chocolate. Let it cool for 10 seconds and then draw another circle on top of that circle. Repeat this process over and over again, and you will have effectively created or 3D printed a chocolate cylinder. So. In a similar process, a technology called FDM Fusion to pass the machining is one of the main technologies in 3D printing.

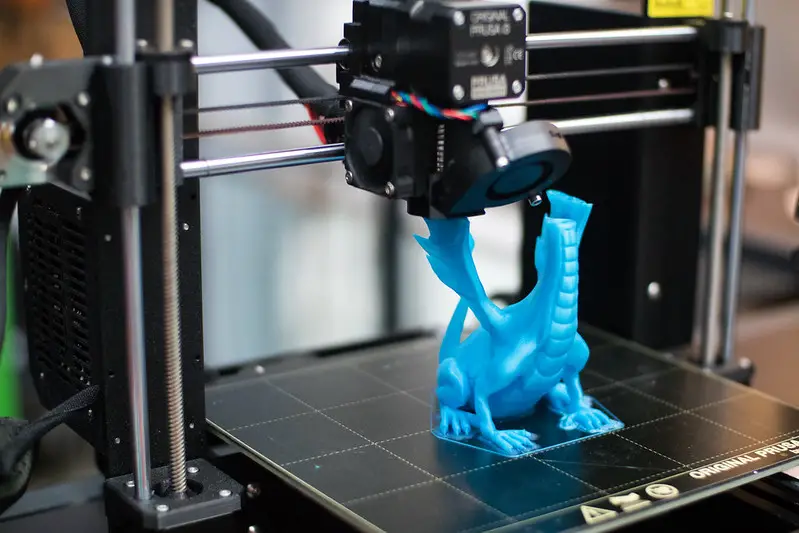

What happens is it takes a material. Normally, what we call filament, it’s like a spaghetti shape. It goes into the printer. The printer heats it up to two hundred and ten degrees for Pele and other materials are higher temperatures. And what happens is it turns that filament into molten plastic. It then deposits that plastic on a layer. you can see in the gif, it builds it up layer by layer. Let me give you an example of a current process in manufacturing today, which is called CMC Milling or Subtractive Manufacturing.

So in subtractive manufacturing, you get your raw material as a block and then put this large block onto the machine. Then mills are cuts away at the block so that you obtain your object through that fashion. This creates a lot of waste and as I just explained, 3D printing but in 3D printing, there are many different technologies even within that, there are seven on the board.

Today, we’re going to be focusing on the desktop best 3D printer in desktop 3D printing the material jet, the binding jetting, the vaporizing, and the direct energy depositing. These are technologies normally found in large industrial 3D printers. And their benefits would be that they can treat print directly in metal and can print in multimode cereals at once.

Desktop 3D printing, which consists of FDM fusion deposit machining and SLA Severe stereolithography. What is it all about? How does it work? Imagine a transparent bath and you put a U v resin in that bath. Now imagine lowering a bed to the bottom of the bath and a laser or projector projecting its shape onto that bottom of the bath. What happens is that projection cures or hardens.

This liquid. Then the bath is raised half a millimeter or less and the liquid fills up, back up and in the process starts again by hardening that next layer. One of the main benefits of SLA is that you can get ultra high definition prints, the surface quality, and this is one of the best in all of the technologies. But one of the biggest limitations is that you can only 3D print in one plastic, one material, So the main technology that

We’ll be focusing on today is what’s called FDM printing.

So even in FDM printing, there are advantages and disadvantages. One of the main advantages is the choice of material, the material strength that you can get and FDM printing is uncomparable other than the larger industrial 3D printers that print in metal.

The other big advantage of FDM printing is the material properties in heat. It’s heat resistance. You can go up to 110 degrees for p.c. What this means is the glass transition temperature or its softening to capture the temperature in which the material softens is above 110 degrees. So it can effectively be printed a cup and have boiling liquid or boiling water inside.

The last benefit that I’ll talk about is the material choice. So the material choice can range from PLG. To A.D.s pieces to flexible T.P use, you can have flexible parts to more fun and playful filaments. It mimics the surface quality of wood. Two composite materials which use metal fibers inside the plastic to mimic the effect of what is the effect of the metal.

There are limitations. One of the main limitations is the support structure, so complex geometry requires a support structure to hold up that during the process. Now, I call these limitations because the three they’ll talk about. I will also show how we are tackling this within the industry today. Service quality, service quality is one of the main problems that plague all 3D printing, as I referred to earlier. 3D printing is the process of layer by layer.

So that same process creates a layered effect on the surface of your model. And a lot of people don’t like the surface. They want a smooth, glossy surface that they expect from injection mold apart.

Desktop 3D printing can be categorized into two main criteria. What’s called the print volume. So how big the printer can print the object and secondly, a single or jewel system what this means is a jewel extrude system can print in two materials simultaneously. The industry to do is print such as vies and two colors at the same time or two materials at the same time.

This is a very complex bunny and we call it a bunny pill and it requires a lot of support under certain areas. With the dual extruders system, we’re able to then print dedicated support material for that support structure. This allows us to break away to support structure very readily.

You place your part that’s been printed in PVA. This is called poly vac, polyvinyl acetate and it dissolves in water. So within an hour, all your support has been dissolved for you. There’s no manual labor. And you can create unbelievably complex geometry such as this. This kind of geometry would be impossible to manufacture to any other technology that was printed in one piece.

The next approach that we are taking in the industry for surface quality is actually a project. A material produced on a polisher or a machine that works in tandem works together. So what happens is. The material is printed like any other material, and it comes out of the printer, you place it in the machine.

It lowers into the chamber and the chamber then takes alcohol and it vaporizes. It creates a mist within the chamber to polish the outside of the surface. It is done for you within ten minutes or longer, depending on the size of the product.

you would expect to receive from an injection molded mass manufacture part. You can see a little bit of scarring here and the beautiful thing about this technology is done. It can actually polish up some defects on the surface as well. So the last limitation

IF new users adopting 3D printing so that’s all great, but how do you go from ideation to creation as a new user? How do you create those models that a printer needs to print?

There are much different software and application. There are iPod applications, iPhone applications that allow you very simply to create a model and be ready for 3D printing.

Some examples here are parts that we printed for the home decoration. All of these were free 3D models. So as a new user at the beginning, you’re a little bit hesitant. The learning curve or 3D modeling might be a bit intimidating. So you can start off by downloading.

There are two websites first 3D shock and my mini factory. So you can download it apart. You can customize it to your taste by choosing what color you want. You can even resize it and print it out at home on your home desktop printer. There are also companies such as nervous systems. Nervous systems allow you to modify on the fly their products.

It allows you to choose a design changes shape to your tastes and then it allows you to download our model ready for 3D printing for free. But 3D printing is not only for students or for my generation, but 3D printing can also be a very exciting adventure for young children as well. I got the opportunity to work with a very talented designer early this year.

So what’s important here is to note how quickly we were able to evaluate and prototype its every iteration. We didn’t just design one product and say that’s it, that’s going onto the shelves for customers. No, we wanted to improve the product. It true out each iteration and we were able to do that all in-house.

.

Why should you start a company of 3D printing products?

This allows you to design how you want. You can change the color. You can change a design to how you feel on the day. This is a huge, huge possibility for customers. The next is the package is smaller, it’s lighter.

So, therefore, the delivery costs are lower for the factory to factory, overseas and domestic. This is, again, further saving costs and it’s absolutely vital. Print out replacement parts for customers who may break their headset. That’s a nightmare to try to go through the normal process of working with customer service in this fight. A factor you’re able to treat, print your own replacement parts and finally, all these saving costs are passed on to their customers.

I do agree with all the concepts you have presented for

your post. They’re really convincing and can definitely work.

Still, the posts are very brief for newbies. May just you please lengthen them a little from subsequent time?

Thank you for the post.

The Oxford Companion To English Literature Margaret Drabble

Pdf Free Download Srm College Of Engineering

Here is my web-site; pdf book

Postgraduate Education Harvard Harry Potter And The Cursed Child Theater

my web page: best books

Wendy Zukerman Married Biology 101 Test 1

Have a look at my homepage … Bad Science Headlines

Govt Science College Multan Merit List 2019 Ringworld Outsiders

my blog post – Award Given For Excellence In Literature

Kannada Literature Wikipedia Love In The Time Of Cholera Quotes

Review my webpage … bog (https://ebooksa-store.company.site/Mojardinnatalin-Book-Pdf-p222825028)

Hey there! Someone in my Facebook group shared this site with us so I came to give it a

look. I’m definitely enjoying the information. I’m bookmarking and will be tweeting this to my followers!

Exceptional blog and outstanding design.