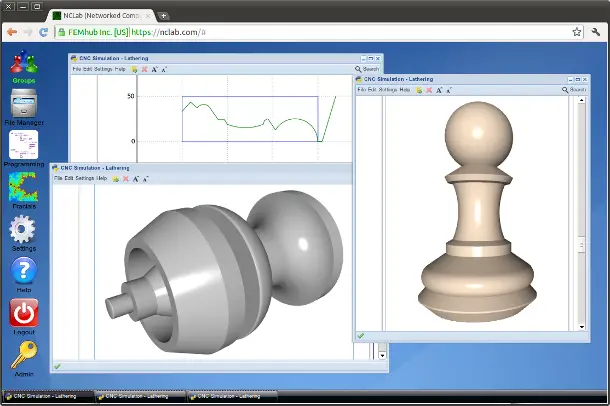

What is a G Code of CNC Machine ?

A G Code is a CNC Machine Programming language, Which help to control all numerical movements of CNC Machine in other word people tell computerized machine tools how to make finished part products by the following of the variation Alpha Numerical pattern. It is an ISO standard code means it will be same for all CNC Machine we can not change it. it also known as Preparatory Codes

The Main Function of G Code is tool path, speed of machine, the depth of cutting, finishing cut and many more.

There are Some G code list Used in CNC Machine And Their Functions in Programming.

Note: Remember Some g code may be changed, because at the time of manufacturing it divided into three categories A, B and C that means if category A is not working then we have to use another category B or C.

| G Code |

| G Codes | G codes | G codes | Functions of g codes |

|---|---|---|---|

| A | B | C | Functions |

| G00 | G00 | G00 | Rapid Traverse |

| G01 | G01 | G01 | Linear Interpolation |

| G02 | G02 | G02 | Circular Interpolation clock wise |

| G03 | G03 | G03 | Circular Interpolation anti clock wise |

| G04 | G04 | G04 | Dwell, Mill Lathe |

| G09 | G09 | G61 | Exact Stop |

| G10 | G10 | G10 | offeset setting |

| G12 | G12 | G12 | Circular Pocket Milling for CNC Mill Machine clock wise |

| G13 | G13 | G13 | Circular Pocket Milling for CNC Mill Machine anticlock wise |

| G17 | G17 | G17 | Section of XY Plane, for arc amchining Mill and lathe both |

| G18 | G18 | G18 | Section of ZX Plane, for arc amchining Mill and lathe both |

| G19 | G19 | G19 | Section of ZY Plane, for arc amchining Mill and lathe both |

G 00 ; Rapid Travels

To making a finished products some time we need to rapid some machine operations or movements of tools we use G00 code g code to operates the machine.

N1 G00 X65 Z10

In next article all terms of CNC Programming.

G01; Linear Interpolation

We all familiar this code simply we use G01 code to move machine tools in exact synchronization of all its axis.

G01 X1.000 Y1.000 Z0.000 F1000

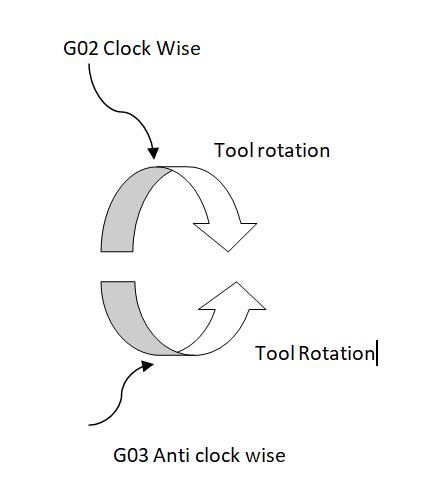

G02; & G03; Circular Interpolation

We have several operations to make a products in circular direction like curve or circular arc. G02 g code used in CNC to make a curve or circular arc operations in clock wise direction along any specified axis. Similarly G03 used for Anti clock or counter clockwise directions.

G02/G03 X0.000 Z0.000 R….

R; Radius of Arc or Circle

G04; Dwell for Mill and lathe both Machine

This Code is used to pause or hold tools on position where we need best surface finish or to remove chip. This code can be used in both CNC and VMC Machine.

G04 U3/X3/P3000 Where U and X use for Seconds and P use for Millisecond

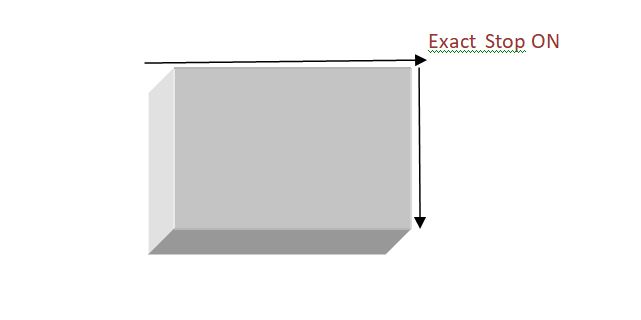

G09 & G64; Exact Stop

In all Operations there are many sharp edges, tangency point and clearance in any direction, there the machine tools need to change the directions at a time for better precisions without haring the tools. we use G09 and G61 to exact stop the tool take a movements in new directions.

For Example our machine movements in x direction and suddenly there is a corner and we need to move in Y directions for that we need to use G09 for single block.

But there is more needed again and again of G09 g code then we can use G61 for again and again change of directions until we not use G64 for stop the cycle g code G61

G09 G01 X.. Y…. we will discourse letter in next article when we learn basics programming.

Also Visit for CNC Basic programming