What Is A CNC Machine ?

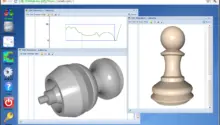

Computer Numerical Control (CNC): A Technology to making a finished products with the help of Pre-Programing by the Computer and Computer control machine called CNC Machine. In this technology a toolpath and machine movement and all machining operation like Finishing, Facing, Drilling, Boring, Threading, Etc (According to products which you have to make) is coded or programed manually or automatic by programmer with the computer software. There are many CNC Software called Computer Aided Manufacturing (CAM) like MasterCAM, HyperMill, NX, CATIA, Solidworks, Fusion 360, EdgeCAM, Etc.

Main Parts Of CNC Machine

Headstock: A main part of CNC Lathe Machine where Motor is mounted. The motor which help to drive the main spindle where chuck is clamped.

Chuck: Chuck is rotating part of CNC Machine where the machining product is gripped. (Main Component which have to made). There is part mounted on chuck which help to hold the parts is called Jaw.

Bed: The Tool is clamped with tool turret which travel on Bed. The Bed is Harden to avoid damage due to tool travelling on that.

Tool Turret: As a mention above Tool Turret is a part on Tool is mounted. It is changed according to tool holder and components shape.

Chuck: It is another important part CNC machine, it is rotating 360 degree. Jaw is a part of Chuck where part which has to machining is clamped.

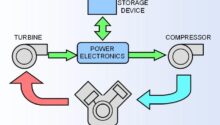

CNC Control Panel: All the operations and movements of tools, axis, and components is controlled by this panel. we can say that it brain CNC. There are several key and one display on this panel where we can start a new program stop/start machining etc. we can see step by step machining on CNC Control panel display.

Tail Stock : Tail Stock is mainly used for grip force from another side of the long machining components.

Most Used CNC Machine worldwide.

There are several types of CNC machine which mention bellow in details

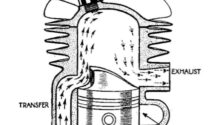

- CNC Lathe/CNC Turning : CNC Turning is generally used to making cylinder, sphere, and conic shapes objects. There is a spindle in CNC machine which is revolving with high speed where object is mounted and make it desire shape as programmed.

- CNC Milling: The technology widely used and giving the good finished products. The Operations is performed in CNC Milling like slicing, cutting and shaving in difference difference directions, angle, depth to cutting a particular pieces.

- CNC Drilling: It is another machine, which works on CNC technology, by this machine we can perform to precise hole with accurate dimension on right place. Manually drilling is difficult, but CNC Drilling make it easy in a good way.

- Plasma Cutter: A plasma nozzle/cutter is used to cut sheets in dimensions with the help of water jet. It is generally used for sheet metal designs.

- CNC Grinder : Grinding is little easy to use and setup as compare to Milling and lathe machine. There is a spinning wheel used to remove materials from workpiece.

Many other CNC Tools we will discuss on the next article like

Wire EDM, Wood Routers, Hot wire foam cutter, water jet cutter, 3D Printing, etc

How CNC Machine Work

Machining is a process to removing material from stock or work process by the several machines like lathe, 3D Printing CNC Machine and many more.

CNC Machine is one of them, CNC (Computer Numerical Control) Machine, work on the principle of Computer control programming. The Program is generated programmer with the help of Computer Aided Manufacturing software according to the objects, machine tools, tool path, and the program is inserted on CNC Control panel we can also manually type program on control panel. and finally CNC operator control that CNC Machine to make a finished products.

Here next article we will discuss step by step programing for CNC Machine

No Responses