What is arc welding?

Arc welding is one of several fusion processes for joining metals. By applying intense heat, metal at the joint between two parts is melted and caused to intermix directly, or more commonly, with an intermediate molten filler metal. Upon cooling and solidification, a metallurgical bond is created. Since the joining is an intermixture of metals, the final weldment potentially has the same strength properties as the metal of the parts. This is in sharp contrast to non-fusion processes of joining (i.e. soldering, brazing etc.) in which the mechanical and physical properties of the base materials cannot be duplicated at the joint.

In arc welding, the intense heat needed to melt metal is produced by an electric arc. The arc is formed between the actual work and an electrode (stick or wire) that is manually or mechanically guided along the joint. The electrode can either be a rod with the purpose of simply carrying the current between the tip and the work. Or, it may be a specially prepared rod or wire that not only conducts the current but also melts and supplies filler metal to the joint. Most welding in the manufacture of steel products uses the second type of electrode.

Basic Welding Circuit

An AC or DC power source, fitted with whatever controls may be needed, is connected by a working cable to the workpiece and by a “hot” cable to an electrode holder of some type, which makes electrical contact with the welding electrode.

An arc is created across the gap when the energized circuit and the electrode tip touches the workpiece and is withdrawn, yet still within close contact.

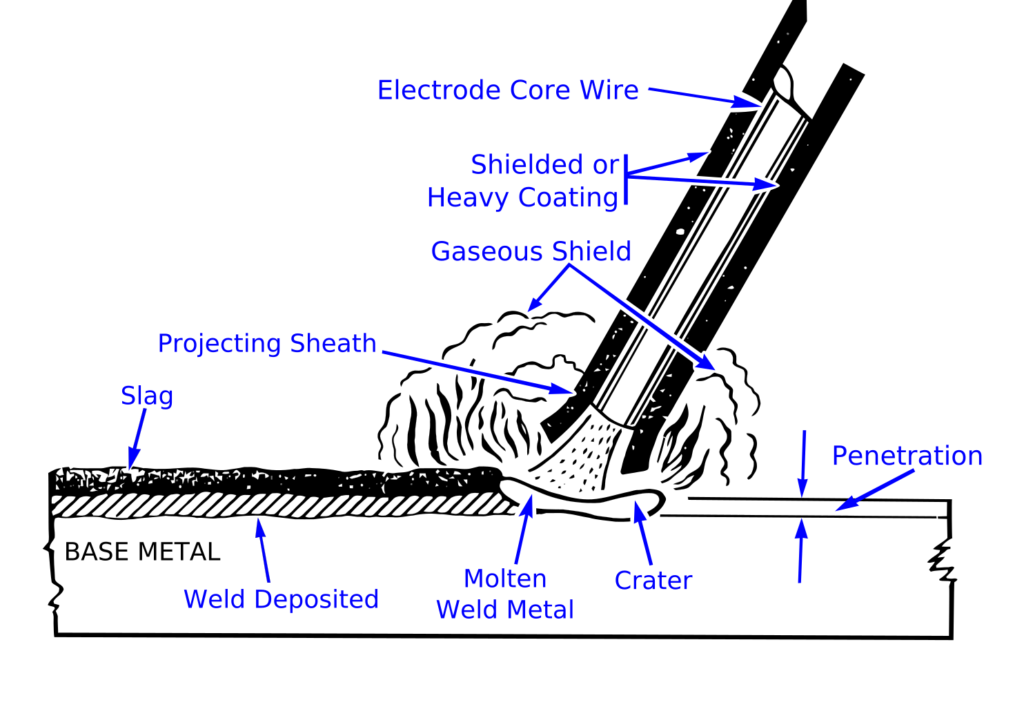

The arc produces a temperature of about 6500ºF at the tip. This heat melts both the base metal and the electrode, producing a pool of molten metal sometimes called a “crater.” The crater solidifies behind the electrode as it is moved along the joint. The result is a fusion bond.

Arc Shielding

However, joining metals requires more than moving an electrode along a joint. Metals at high temperatures tend to react chemically with elements in the air – oxygen, and nitrogen. When the metal in the molten pool comes into contact with air, oxides, and nitrides form which destroy the strength and toughness of the weld joint. Therefore, many arc-welding processes provide some means of covering the arc and the molten pool with a protective shield of gas, vapor, or slag. This is called arc shielding. This shielding prevents or minimizes contact of the molten metal with air. Shielding also may improve the weld. An example is a granular flux, which actually adds deoxidizers to the weld. the welding arc and molten pool with a Stick electrode. The extruded covering on the filler metal rod provides a shielding gas at the point of contact while the slag protects the fresh weld from the air.The arc itself is a very complex phenomenon. An in-depth understanding of the physics of the arc is of little value to the welder, but some knowledge of its general characteristics can be useful.

Nature of the Arc

An arc is an electric current flowing between two electrodes through an ionized column of gas. A negatively charged cathode and a positively charged anode create the intense heat of the welding arc. Negative and positive ions are bounced off of each other in the plasma column at an accelerated rate.

In welding, the arc not only provides the heat needed to melt the electrode and the base metal, but under certain conditions must also supply the means to transport the molten metal from the tip of the electrode to the work. Several mechanisms for metal transfer exist. Two (of many) examples include:

- Surface Tension Transfer – a drop of molten metal touches the molten metal pool and is drawn into it by surface tension

- Spray Arc – the drop is ejected from the molten metal at the electrode tip by an electric pinch propelling it to the molten pool (great for overhead welding)

If an electrode is consumable, the tip melts under the heat of the arc and molten droplets are detached and transported to the work through the arc column. Any arc welding system in which the electrode is melted off to become part of the weld is described as metal-arc. In carbon or tungsten (TIG) welding there are no molten droplets to be forced across the gap and onto the work. Filler metal is melted into the joint from a separate rod or wire.

More of the heat developed by the arc is transferred to the weld pool with consumable electrodes. This produces higher thermal efficiencies and narrower heat-affected zones.

Since there must be an ionized path to conduct electricity across a gap, the mere switching on of the welding current with an electrically cold electrode posed over it will not start the arc. The arc must be ignited. This is caused by either supplying an initial voltage high enough to cause a discharge or by touching the electrode to the work and then withdrawing it as the contact area becomes heated.

Arc welding may be done with direct current (DC) with the electrode either positive or negative or alternating current (AC). The choice of current and polarity depends on the process, the type of electrode, the arc atmosphere, and the metal being welded.

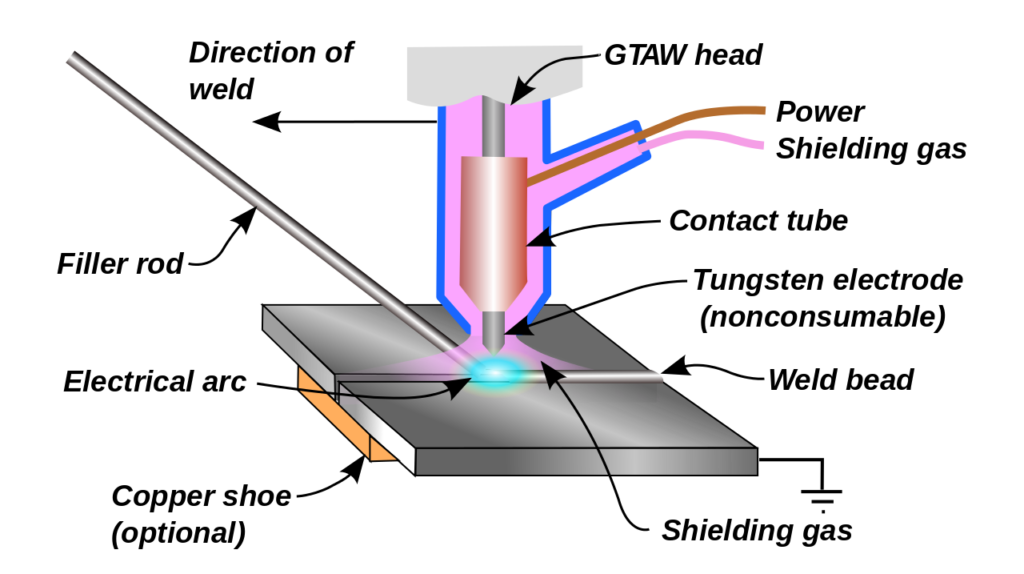

What is TIG Welding?

TIG Welding, also known as Gas Tungsten Arc Welding (GTAW), is a process that joins metals by heating them with an arc between a tungsten electrode (non-consumable) and the workpiece. The process is used with shielding gas and may also be used with or without the addition of filler metal. The primary variables in TIG Welding are arc voltage (arc length), welding current, travel speed, and shielding gas composition. The amount of energy the arc produces is proportional to the current and the voltage. The amount of energy transferred per unit length of the weld is inversely proportional to the travel speed. Shielding gases are

typically inert to protect the electrode from contamination. The use of helium shielding provides more penetration than argon. The arc, established between the tip of the electrode and the work, generates heat to melt the base metal. Once the arc and weld pool is established, the torch is moved along the joint, and the arc progressively melts the surfaces to be joined. If used, filler wire is usually added to the leading edge of the weld pool to fill the joint. The tungsten electrode can be alloyed with small amounts of active elements to increase the emissivity of the electrode; this provides quicker arc starting, greater arc stability, and longer electrode life.

Also Read What is Scavenging in IC Engine ?

Turbocharger and Hybrid Turbocharger?

Here is the video Tutorial

No Responses